Cellulosic Polymer Micro Fiber - PCM

PCM is a micronized cellulosic material with polymeric compounds, whose cellulose microfibers can interact physically on the medium’s surface area and chemically through hydrogen bridge bonds.

It exhibits different geological and mechanical properties depending on its use, giving a unique combination to various systems and applications.

As a result of this polymeric microfibrillation process, many of these hydroxyl groups become accessible to the matrix in a network, which in turn provides a very high water retention capacity and the special characteristic of compacting or crystallizing after use.

This yields a robust product that improves the elastic limit, versatility, and flexibility in the different formulations in which it is applied, substantially enhancing the sustainability profile.

Uses of PCM

Oil Industry Applications

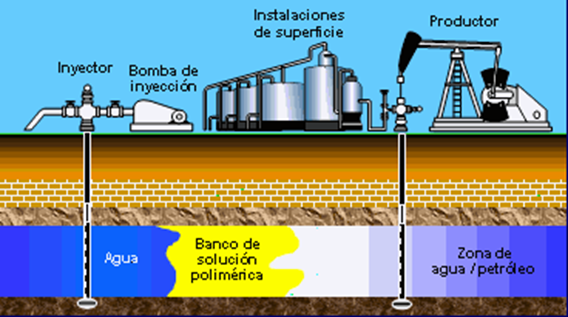

PCM is used in the oil industry for assisted secondary and tertiary recovery. Its main function is to densify the injection water that pushes the oil toward the production well.

By increasing the viscosity of water—which normally has a density of 1 g/cm³—to a level close to or higher than that of the oil, PCM allows the injected water to act more effectively as a piston. This results in a higher percentage of oil being extracted instead of water, significantly improving production performance and efficiency.

Agricultural Applications

In agriculture, PCM is highly valuable for its unique ability to absorb and retain water. As a polymeric microfiber, it can encapsulate and store water, expanding up to 20 times its dry weight, making it an excellent underground water reservoir.

This product is applied in various crops, such as fruit trees (e.g., walnuts, almonds, vines). It is typically placed 40–60 cm deep in a circular pattern around the tree trunk, forming a basin with a diameter of about 2 meters. Once buried, the soil is covered, leaving a small surface basin to retain available irrigation or rainwater.

As the water penetrates the soil, PCM absorbs it and swells, acting as a “lung” or underground water cushion. This allows the plant to draw moisture as needed during growth and fruit development, even in drought conditions.

PCM is derived from natural cellulose fibers obtained from wood, processed into a powder and polymerized to create intercellular spaces that function as water reservoirs. It is biodegradable, organic, and environmentally safe. It does not harm plants; rather, it improves survival and growth in dry or poor soils. Nutrients like urea, phosphate, or nitrogen-based fertilizers can be added during application to enhance its agricultural benefits.

Its effective lifespan in soil is approximately two years, during which it stores water underground and discards any excess, maintaining optimal hydration levels during dry periods. This makes it possible to rehabilitate and cultivate arid or desert zones.

Pellet Form for Desert Farming

PCM is now being developed in pellet form—either pure or combined with essential nutrients. These pellets are designed for direct seeding in desert or arid areas, enabling the cultivation of crops such as wheat, corn, or legumes with minimal irrigation (e.g., drip or occasional rainfall).

The application involves a mechanical process: a furrow opener is followed by a roller, a pellet dispenser places PCM pellets into the furrow, followed by a seed planter depositing the grain, and a final roller closes the system. The small amount of water available will be retained below the surface by the PCM, supporting germination and crop growth.

This method is repeated annually, with leftover PCM in the soil contributing as organic fertilizer. Nutrient-rich pellets containing nitrogen, phosphorus, urea, and even magnesium sulfate (agricultural gypsum) can be used to address acidity or nutrient deficiencies.

Social Impact

The primary goal of PCM in agriculture is to contribute to food security by enabling cultivation in areas previously considered unsuitable due to aridity or infertility. This innovative solution offers a sustainable way to fight hunger by expanding arable land in critical regions around the world.

Composition and Physical Properties

Physical Appearance:

Agglomerated white polymeric cellulosic microfibers

Fiber Length: 5 – 10 microns

Fiber Thickness (Diameter): 50 – 100 microns

Water Dispersion: 100%

Polymer Content: Up to 5%

Density: 0.16 g/cm³

Solubility in HCl at 100°C (212°F): 90%

Viscosity: At temperatures below 80°C, with a 2% solid concentration in water: 150 cps

Advantages, Application Details and Use in Different Scenarios

- Does not require additional additives.

- Compatible with both fresh and seawater.

- Easily mixes and disperses in water and in the intended media.

- High viscosity under low shear conditions.

- Thixotropic characteristics.

- Very high water retention capacity.

- Acts as a barrier material.

- Enhances the absorption of active ingredients, ensuring stability.

- Does not degrade in water.

- Thickening mechanism does not rely on alkali activation.

- Composed of highly entangled fibril aggregates dispersed in water (not dissolved).

- Interacts both physically and chemically with its environment.

- Stable viscosity across a wide range of pH levels, temperatures, and salt concentrations.

- Good compatibility with solvents, surfactants, salts, etc.

- Excellent bridging material, with proven effectiveness in a variety of applications as previously described.

- Among the most important uses is its application in Enhanced and Tertiary Oil Recovery in mature and depleted wells.

- Also suitable for use in concrete and oil well cement slurries.

- Recommended dosage: 2% by weight of the material to be treated, whether water, concrete, or other uses such as briquetting.

- Whenever possible, start with PCM (2%) to facilitate positive laboratory test results. This percentage can be increased if necessary.

- Ensure a homogeneous dispersion free of lumps or visible aggregates.

· Immediate sedimentation or phase separation may also indicate insufficient dispersion

Uses in the Oil Industry / Enhanced and Tertiary Oil Recovery

Oil recovery involves many different working fluids that are pumped into the reservoir to extract the crude oil trapped underground. For example, during the drilling phase, drilling fluid or mud is used to cool the drilling equipment, transport cuttings to the surface, and deliver the necessary chemicals required for the drilling process.

Hydraulic fracturing fluids are essential to facilitate the flow of oil toward the wellbore. As the well ages and production declines, oil recovery can be enhanced by injecting displacement fluids that push the remaining trapped oil toward the producing well.

In drilling fluids, it is important that the fluid flows easily and can be pumped efficiently. At the same time, it must have sufficient viscosity to carry cuttings.

PCM is extremely thin compared to commonly used viscosifiers such as xanthan gum. Although PCM has a viscosity up to 100 times higher than xanthan gum at low shear rates (essentially at rest), under shear its viscosity is lower than that of xanthan gum.

In other words, PCM offers better stabilization while also being easier to pump than xanthan gum solutions.

Moreover, PCM can be used to transport small particles into the reservoir through fracturing fluids, as it keeps them suspended in water while still maintaining good flowability. Even cement used in oil wells requires stabilization and fluidity, which PCM can contribute to effectively.

The significantly higher viscosity at low shear rates shown by PCM is evidence of the product’s stabilizing potential.

Rheology agents in working fluids must withstand the demanding conditions found in oil wells. For example, the salt concentration in these fluids often becomes extremely high, and both temperature and shear stress increase significantly.

PCM retains its rheological properties even at high salt concentrations and remains stable at elevated temperatures. Additionally, PCM is highly shear-stable, meaning it can be mixed and pumped at high intensities without losing its rheological effect. Xanthan gum and other polymeric rheology modifiers are typically shear-sensitive, as their polymer chains begin to break under such conditions, resulting in a loss of stabilizing and thickening effects over time.

PCM’s rheological properties meet many of the performance requirements for working fluids used in oil recovery. Combined with the fact that it is made from polymeric microcellulose—the most common natural polymer—this makes PCM safe for both workers and the environment.

This product was specifically designed for use in Enhanced and Tertiary Oil Recovery.

When Primary Recovery does not include any type of reservoir assistance and Secondary Recovery involves only water injection to better sweep hydrocarbon systems, Tertiary Recovery encompasses a broader range of enhanced recovery methods. These include steam, gels, CO₂, chemicals, and other techniques aimed at improving volumetric sweep efficiency and mobilizing the oil bypassed during secondary recovery.

In our case, we have developed a superior solution: PCM, a polyanionic micro/nanocellulose fiber that is mixed with water—typically at just 2% concentration—and then injected into the well under pressure.

This always follows the first stage of the process: the prior application of AR – Reclaimed Oil Field, which is left to act on its own for 8 to 10 hours, without adding water.

Only after this time has passed is the second product applied—PCM mixed with water and injected under pressure.

This product or system is intended for use in sweep fluids for Enhanced and Tertiary Oil Recovery, displacing hydrocarbons toward the nearest producing well—generally within a radius of 200 to 400 meters.

The technique recommends activating 5 to 8 shut-in wells surrounding a single producing well.

It is important to note that, whereas previously one might extract around 50 m³ of water and only 1 m³ of oil, this process can shift that ratio significantly—enabling extraction of 20% to 30% of the remaining oil in the subsurface. This greatly increases oil production and proportionally reduces water usage.

A key factor to consider is the density of the oil to be recovered. We base our calculations on an average hydrocarbon with a viscosity ranging from 120 to 150 cps at temperatures below 80°C.

We need to know this data in order to calculate the appropriate percentage or dosage of both PCM and AP – Reclaimed Oil Field to be used.

If we are dealing with a hydrocarbon like the one described previously, the PCM dosage should be 2% by weight in the water to be mixed, stirred, and injected, in order to achieve a viscosity of 150 cps.

In the case of heavy crude oil, based on its viscosity (in cps), the PCM dosage may be increased by 1–2% to match the density of the injected water (with product) to that of the oil.

This allows the water to act like a piston, pushing hydrocarbons rather than water toward the producing well.

It is also advisable to slightly increase the PCM concentration as recovered production starts to decline.

From the beginning, emphasis was placed not only on the effectiveness of this technology but also on the importance of significantly reducing recovery costs.

PCM, made of microfibrillated cellulose, is recognized as an environmentally friendly and safe rheology modifier for the oil recovery industry.

This system does not cause pipe corrosion and also reduces the need for pulling operations, which previously had to be carried out periodically—thereby avoiding that additional cost.

As for usage, it is recommended to have a pump in each well to be treated, in order to properly distribute the flow in each one.

The system works well in poorly consolidated zones with wormhole formations, where the product naturally acts by blocking those channels and restoring sweep efficiency.

The oil company is facing the decision to shut down less efficient zones in order to avoid a sharp increase in the operational cost of the field. Additionally, the mobility ratio of the reservoirs is highly unfavorable, which results in very inefficient recovery.

This situation led us to develop our own PCM product, based on polymeric nanocellulose fibers, creating a new technology that allows us to control the push fluid density (in cps) to levels higher than that of the oil itself. In this way, tertiary recovery becomes more effective, as the sweep is significantly superior to that achieved using water, steam, or traditional polymers.

Instead of recovering 50 m³ of water and only 1 m³ of oil from the producing well, the ratio improves considerably—making it possible to drastically increase the extraction of trapped hydrocarbons while simultaneously reducing the injected water volume by 50% or more. This greatly increases the profitability and efficiency of the recovery process without negatively affecting the productive zone.

Use in Oil Recovery

For secondary and tertiary recovery in mature wells, in combination with the product Recovery Oil Field.

Use in Agriculture

As a water-holding and storage product below the soil surface in arid regions.

Handling and Toxicity

PCM should be handled like any other industrial chemical product, using personal protective equipment and following the precautions indicated in the Material Safety Data Sheet (MSDS) and Transport Safety Data Sheet.

Packaging and Storage

PCM is supplied in volumetric containers, with capacity expressed in cubic meters due to its low density, or in lightweight paper bag packaging.