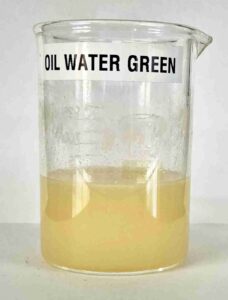

OIL WATER GREEN

OIL WATER GREEN This new product developed by the company Allpetrol SA, called and patented as Oil -Water Green, for the treatment of wastewater from the oil industry, whether from Frack or from the cleaning of facilities and locations, producing not only a substantial reduction in the ppm of hydrocarbons, but also the reduction and elimination of many of the products detailed as hazardous constituents for the quality of irrigation water, according to Annex II Table 5 of Law 24051 on hazardous waste of the Argentine Republic.

This product is chemically composed of non-harmful, non-polluting substances that produce a chemical and physical reaction lasting three hours, clarifying the water and reducing levels considered hazardous.

Before beginning the recovery of the water batch, it is important to measure the ppm of total petroleum hydrocarbons present in the water in order to determine the appropriate dosage of OIL WATER GREEN for its remediation.

Composition and Physical Properties

Physical Properties:

Physical Appearance: Whitish liquid

Coefficient of miscibility in water: Infinite

Specific Gravity: 0.98 – 1.01 g/cm³

Recommendation: Pre-analyze contaminated water to determine the ppm hydrocarbon content and then, after treatment, analyze the ppm of total petroleum hydrocarbons (TPH) it may contain.

Features

The objective of this product is to process this contaminated water, transforming it back into improved and recovered water for industrial use and its subsequent reuse in the reservoir and for irrigation.

Advantages

• Contaminant-resistant.

• Compatible with a wide variety of water-based systems and concentrated sanitation solutions.

• Environmentally friendly, as it does not contain toxic volatile compounds.

• Easy to handle and mix.

• Powerful bactericide and fungicide

Application details

It is important to note that this entire analysis and the creation of this new product were formulated based on the sample received. There is a 10% limit for water in poorer condition, and no more. This dosage is attached. The dosage is determined by the oil level in the sample to be treated. This dosage is 10% of the oil content in the medium. If the water is another type, containing higher amounts of hydrocarbons or chemicals, the water to be treated must be analyzed beforehand and another formulation developed for that water sample.

If the tank is 50,000 L, this would be proportionally 1,000 L of OIL WATER GREEN. Let it stand for about two hours and, after observing the clarified water, pump it out onto a tanker truck to take it to the drilling site.

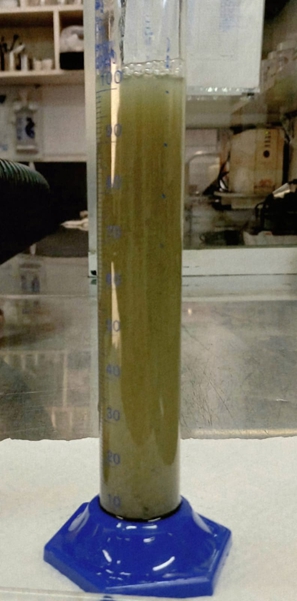

This product precipitates the solids present in the treated sample and degrades the liquid contaminants.

The water is left in Class 5 industrial use conditions, according to the safety table for liquids contaminated with oil.

If the tank is 50,000 liters and the amount of oil is approximately 1000 liters, 10% of green water oil must be added, which means 100 liters of reagent is added to the tank above it and is left to act and rest for a period of 24 hours, during this time the reaction is carried out producing the precipitation of solid contaminants and leaving the supernatant clean to be reused industrially. The deposited solids are extracted and dried, it does not contain contaminants and can be added to the soil.

Management and Toxicity

Handle as an industrial chemical, wearing personal protective equipment and following the precautions described in the Material Safety Data Sheet (MSDS). This product is made from environmentally friendly raw materials.

Packaging and storage

OIL WATER GREEN It comes in 20L buckets or 200L drums. It is recommended to store in a dry area, away from heat or ignition sources, with minimal dust.