AETHER

AETHER™ is an advanced ecological solution developed to biorremediate combustion gases generated from fossil fuels such as coal, petroleum, and hydrocarbon derivatives. It is specifically designed for application in industrial furnaces, waste incinerators, cement kilns, power plants, steelworks, and smelting operations, where combustion processes emit large volumes of greenhouse gases and toxic pollutants. The primary objective of AETHER™ is to significantly reduce emissions of CO₂, N₂O, SO₂, and other complex hydrocarbon chains, mitigating their environmental impact and enabling compliance with increasingly stringent international emission standards. Unlike conventional chemical treatments, AETHER™ leverages a proprietary formulation of organic plant-derived terpene solvents and natural surfactants, ensuring high efficiency, ecological safety, and complete absence of hazardous compounds such as BTEX (benzene, toluene, ethylbenzene, xylene).

Uses of AETHER S (simple) in Permafrost for the reduction of greenhouse gases

In the reduction of greenhouse gases, there is a challenge that had not been taken into account before. There is a factor that is not being considered in global warming and, therefore, in the advancement of climate change, and that is the melting of the permafrost, which today represents a threat in global warming due to the emission of greenhouse gases.

As a result of global warming, these layers of tundra that used to be frozen are now thawing, and they are producing a very large amount of greenhouse gases.

For that reason, we include the product Aether, developed to eliminate the pollution caused by greenhouse gases produced by the burning of fossil fuels and hydrocarbons. We have found that an effective way to reduce these emissions from permafrost is to spray the reactive fluid of Aether from helicopters over the surface of the permafrost, so that when it melts — which will be inevitable — the emission of greenhouse gases can be treated from the ground, breaking them down on-site and releasing only oxygen, hydrogen, and nitrogen into the atmosphere, while leaving heavy elements in the soil and breaking the carbon chains. In this way, it is possible to reduce the pollution that is increasing day by day.

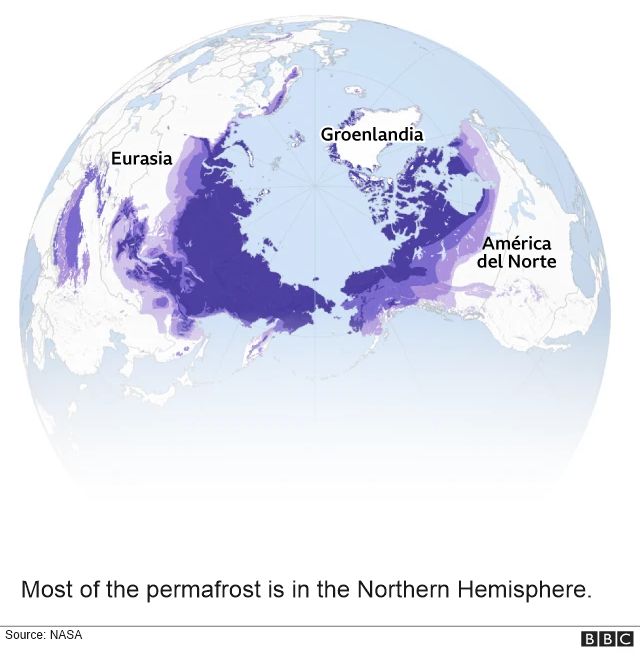

Permafrost is the name given to this layer that forms containing large amounts of organic carbon in the form of plant and animal remains that have not decomposed due to the cold in these Arctic areas, and parts of Alaska, and also in Asia, where there is permafrost because of below-zero temperatures. The presence of these materials gives the terrain a special characteristic, acting as a hard layer that, in some cases, is more resistant than concrete when frozen.

The problem we are experiencing today is that, due to the high global temperatures, these layers of material are thawing and releasing a large amount of greenhouse gases such as methane and carbon dioxide.

That is why we suggest applying the Aether product by spraying it through the air over the permafrost soil, so that as it begins to thaw and microbes start decomposing the organic matter and forming greenhouse gases, these gases come into contact with Aether and are broken down, preventing the greenhouse gas effect of harmful gases.

To get an idea of the size of the permafrost, it can reach thicknesses greater than 600 meters deep and have a temperature of between –9 and –11 °C. That gives us a picture of the environmental damage we face if we don’t do something effective to control this melting and the emission of greenhouse gases.

PERMAFROST EXPANSION

Permafrost emits approximately 600 million tons of greenhouse gases per year.

It is estimated that permafrost contains 1.5 trillion tons of greenhouse gases, including both CO₂ and methane — double the amount that exists in the atmosphere.

It is estimated that around 10% will be released into the atmosphere before 2100. It all depends on global warming. As the permafrost melts, microbes decompose the organic matter and produce emissions.

Composition and Physical Properties

The formulation of AETHER™ is based on an ecological synergy of organic plant terpene solvents and natural surfactants. It contains no toxic hydrocarbons or petrochemical derivatives, ensuring environmental and operational safety.

Physical and Chemical Characteristics:

Physical Appearance: Light blue liquid

Odor: Terpenoid

Specific Gravity: 0.9 (68° F) 20° C

Water Solubility: Soluble

Autoignition Point: 360° C

Flash Point: 180° C

Ph (20° C) 3.5

The product exhibits a negative enthalpy of formation, releasing heat into the environment during its reactions, which contributes to increased entropy and facilitates the breakdown of carbon chains in emitted gases.

Mechanism of Action

AETHER™ operates through a molecular disruption mechanism that directly interacts with toxic gases produced by combustion. When atomized in combination with neutral water (pH 7) and applied as a fine spray over emission streams, AETHER™ initiates a chain-breaking reaction on carbon-based compounds.

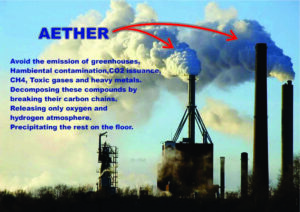

• Primary Effect: Breaks down long carbon chains (e.g., CO₂, CH₄, NOₓ, SOₓ) into lighter, volatile elements such as oxygen (O₂), nitrogen (N₂), and hydrogen (H₂), safely released into the atmosphere.

• Secondary Effect: Condenses heavier elements (carbon, sulfur, heavy metals, and complex residues) into solid particles or pellets that fall to the ground, enabling safe capture and disposal.

• Final Disposal: These solid residues can be palletized and injected into depleted oil wells (average 3,000 m depth), ensuring permanent sequestration and preventing recontamination.

This process leverages entropy increase to facilitate the breakdown of pollutant gas chains, consistent with the second law of thermodynamics.

Applications

- Coal-fired power plants

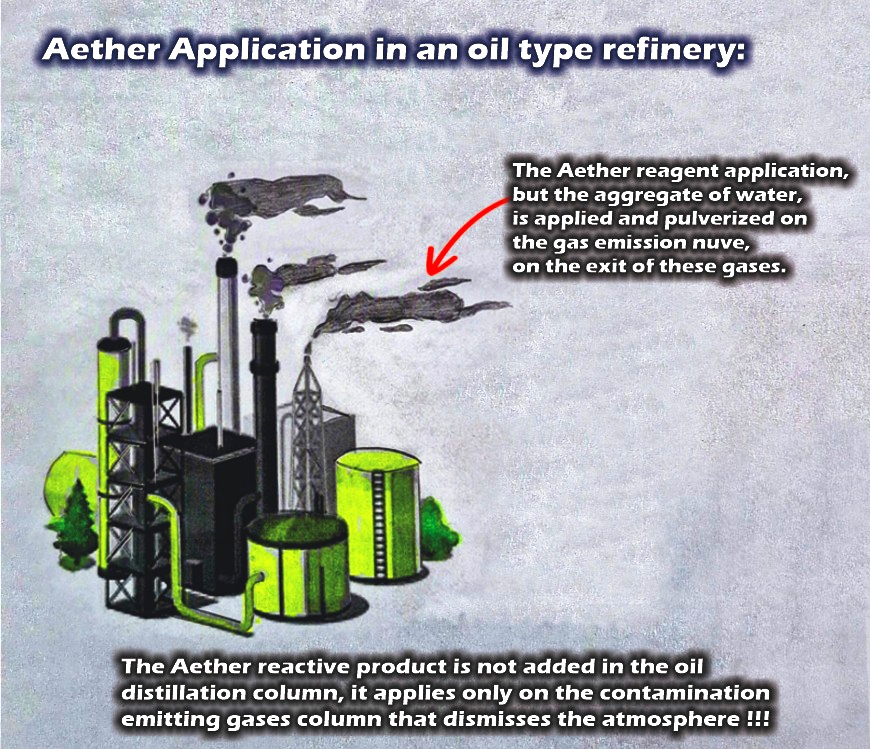

- Petroleum refineries (post-combustion treatment only)

- Cement kilns

- Steel mills and foundries

- Waste and garbage incinerators

- Hydrocarbon-based industrial boilers

Critical Safety Note: Never apply AETHER™ directly to fuels (coal, coke, petroleum, fuel oil) or into distillation towers, as extreme temperatures (300–500 °C) could cause uncontrolled gas expansion and structural failure. Application is exclusively at the emission outlet via fine spray atomization.

Advantages

- High efficiency in breaking down carbon chains and reducing GHGs

- Eco-safe composition, free from BTEX and toxic hydrocarbons

- Excellent particle disperser for optimal gas interaction

- Pleasant odor due to terpene-based solvents

- Reduces risk of acid rain and smog formation

- Enables safe capture and sequestration of heavy pollutants

- Contributes to compliance with international emission standards (EU, EPA, ISO)

Conclusion

AETHER™ represents a state-of-the-art ecological solution for the remediation of industrial combustion gases, providing an effective, safe, and environmentally responsible approach to reduce greenhouse gas emissions and other toxic pollutants. Its plant-based terpene formulation enables the breakdown of complex carbon chains, the release of lighter, non-toxic elements, and the safe sequestration of heavier residues. Applicable across multiple sectors—including power generation, steel production, cement manufacturing, and waste incineration—AETHER™ demonstrates both versatility and scalability, supporting industries in achieving carbon neutrality and ecological preservation.

Summary of the use and application of AETHER™

My name is Rafael Ferreyra. I am an engineer at Allpetrol S.A., head of the New Ecological and Environmental Developments Department. My goal is to contribute to mitigating the planet’senvironmental pollution. I would like to clarify that the use and application of Ether has been somewhat misunderstood. This product is designed exclusively for use in refineries, cement kilns,power plants, foundries, or other facilities where fossil coals or hydrocarbons are used for combustion. These processes are responsible for the emission of approximately 3 tons of CO₂ forevery ton of fossil coal or hydrocarbon used.

It is important to emphasize that, under no circumstances, should Ether be introduced into a distillation tower (oil cracking) or mixed directly with fuels such as coal, coke, or fuel oil, or withany other type of fuel. This is because, logically, the high temperatures reached (between 300° and 500° Celsius) would produce a gas expansion that could cause the rupture of operatingindustrial plants. In all cases, ether must be applied at the end of these processes, that is, at the outlet of the polluting combustion gases responsible for the greenhouse effect. AETHER™ is atomized or sprayed, applying it to the cloud of polluting emissions.

It should never be added directly to coal or any type of hydrocarbon fuel.